Quality Process

“At Saahaj, Quality is everyone’s responsibility. Saahaj is committed to supply Milk and Milk Products confirming to all the relevant food safety and quality standards. To enhance our competitive advantage, we continually strive to apply the highest quality and regulatory standards, in procuring and delivering safe and quality milk & milk products to satisfy our customers’ / consumers’ needs.”

Driving growth through Quality………..

- Our main object is to serve the farmers and helping them for their socio-economic development, and provide safe and quality Milk & Milk Products to our Customers / Consumers.

- Our reputation for quality is a great competitive advantage to us. It’s an advantage we guard carefully, taking responsibility for our part in maintaining the trust of our customers and consumers.

- To maintain and expand our market leadership as well as to meet the growing demand of safe and quality Milk and Milk Products, the Quality Assurance Department at Saahaj MPCL is committed to improve the quality and safety of our Milk and Milk Products in conformity of various national as well as international regulatory requirements / standards in accordance to the Industry norms also

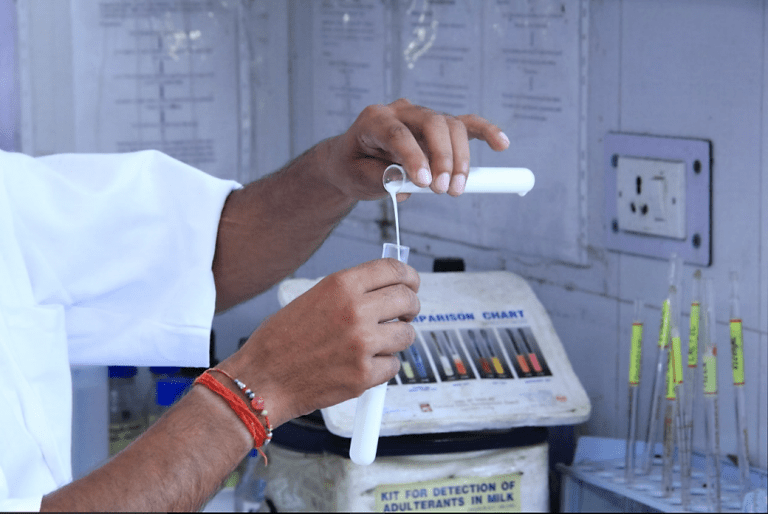

- For the above mentioned purpose we have developed the complete testing facilities at all of our Milk Chilling Centers for checking Chemical and Bacteriological quality of milk as well as any kind of adulteration. We have arranged highly sophisticated analytical equipment like Sodium Ion Meters, Digital BR Meters, Milk Analyzers, RM Testing facilities, Remi centrifuge, Vortex Shakers etc. at all of our MCC’s to check the quality of Milk received / dispatched.

- We implemented procedures to track improvement and deviations in Milk Quality at each stage of supply chain through Quality Assurance Application & MIS system, where by various quality records are received & checked in real time. We also conduct unannounced visits / audits at our Milk Collection & Chilling facilities to carryout different quality tests in order to improve & maintain our Milk Quality, and also to look for any potential weaknesses in chain & to overcome them effectively in a planned manner.

- To ensure safety of our products, we implemented a number of demanding Quality Control Systems and Procedures. The Company also launched an incentive plan to improve raw milk quality (MBR Time Basis) throughout the supply chain in Field. The regulations (FSSAI, Legal Metrology, GMP, GHP etc.) concerning Quality Assurance & Control in our dairy business are implemented & followed strictly at all of our Milk Collection and Chilling Centers.

- Our highly trained team ensures that we always meet or exceed all the relevant quality, food safety and regulatory requirements. To strengthen our quality standards, we provide training modules to our Lab Incharge / Chemists / Quality Personnel’s for avoiding any loss of quality, fulfilling our own demands for continuous improvement & future plans for providing our consumers Good Quality and Safe Milk and Milk Products. The training programmes covered about Milk Testing Methods, FSSAI norms, Hygiene & Food Safety, Good Manufacturing Practices & Clean Milk Production, Cleaning in Place & Good Lab Practices etc. to enhance the quality and safety of Milk and Milk Products.

- Our Mutually beneficial relationships with farmers through education and need based training leads to better quality milk.We consistently procure quality & safe milk through hygienic and controlled processing and modern technologies, with sufficient quality checks at each stage from MPPs / BMCs till MCC Dispatch Dock.

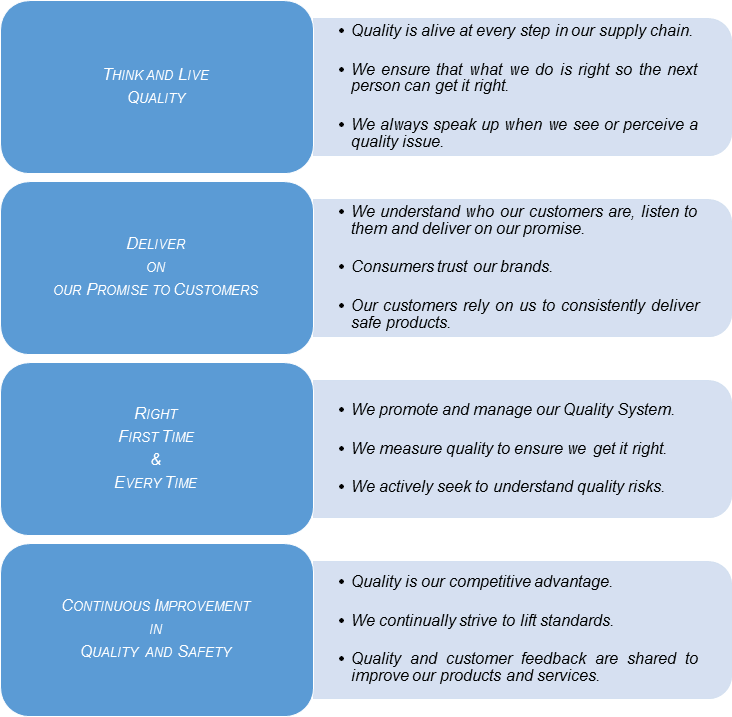

Quality Principles

We stand for uncompromising standards of quality, safety and integrity.